Liquid flow sensors for medical technology

Honeywell's liquid flow sensors are based on an innovative thermal flow sensor that is in direct contact with the measured medium and offers unparalleled accuracy and sensitivity. This is ideal for medical technology and biotechnology. Dialysis, urology, infusions—this high-precision sensor specializes in these areas. With a flow rate of 0 ml/h to 400 ml/h, it is particularly capable of controlling highly precise dosages.

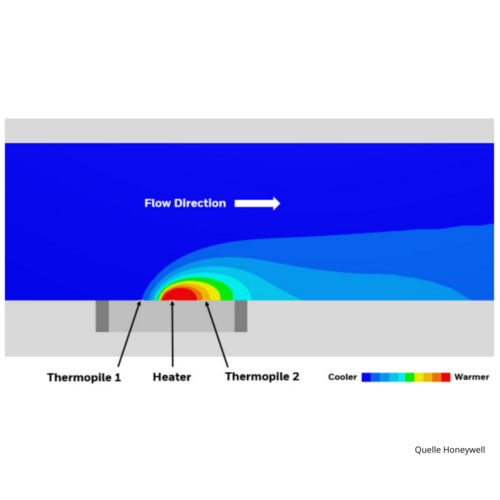

Operating principle

The Honeywell Liquid Flow Sensor operates on the principle of convective heat transfer. A heating element slightly increases the temperature of the liquid, and two thermopiles measure the temperature difference on both sides of the heating element. This temperature difference is used to calculate the flow rate of the liquid. The amount of heat dissipated is proportional to the thermal properties and flow rate of the liquid.

The temperature of the liquid is only increased near the sensor element and does not increase the temperature of the liquid leaving the sensor.

When liquid conditions become unstable, such as when the thermal conductivity of the liquid increases or decreases, the high sensitivity of the liquid flow sensor detects these fluctuations and signals to the system that changes are occurring in the liquid.

All Honeywell liquid flow sensors undergo extensive calibration procedures to ensure linear output. Honeywell liquid flow sensors are factory calibrated for pure water, but can also be calibrated for other liquids to meet the requirements of most applications.

High adaptability

If your application requires it, Honeywell can customize the sensor to create an all-in-one solution that integrates the sensor and microprocessor into a single component. All-in-one solutions are typically used in space-constrained applications, such as portable products that require an even more compact housing. Custom flow calibration is also possible.

Distinguishing between different technologies

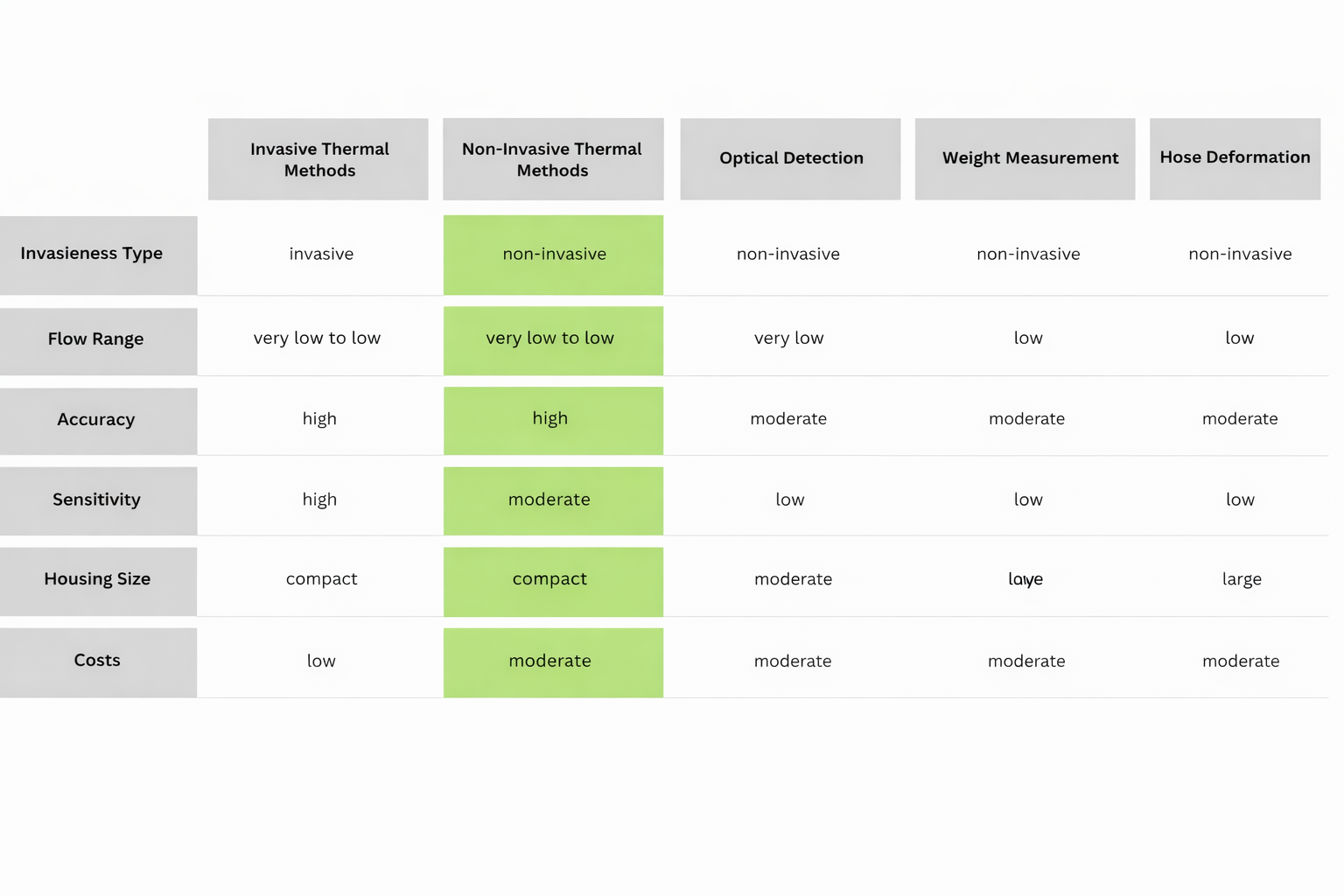

There are a variety of technologies available on the market today for measuring liquid flow, which can sometimes make it difficult to choose the right technology for your application. Some of the most common technologies used in low-flow applications are:

- Thermal flow measurement

- Optical drop detection

- Liquid weight measurement

- Tubing deformation measurement

Each of these technologies has advantages and disadvantages depending on the requirements of the application. Several factors must be considered when selecting the right flow sensor for your application, including:

- Should the measurement be invasive or non-invasive?

- What flow range is required?

- What accuracy/sensitivity does the application require?

- Housing size/installation space

- Cost

The Honeywell liquid flow sensor is ideal for applications that require high sensitivity for low flow ranges and allow non-invasive flow measurement.

The following table provides a simple comparison between common flow sensor technologies as a guide for selecting the right flow sensor type based on application requirements.