Level measurement with pressure sensors

At IBA Sensorik, we offer innovative solutions for the precise measurement and monitoring of fill levels in a wide range of applications. With Honeywell Sensing and Safety Technologies, we have one of the market leaders in the sensor technology industry at our side. Our measurement with pressure sensors is a proven method for accurately recording and controlling fill levels in containers.

Hydrostatic level monitoring

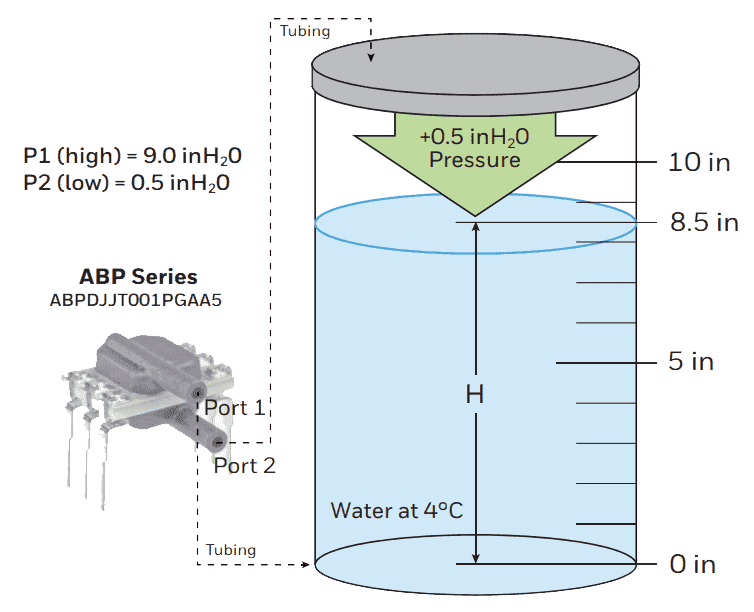

Hydrostatic level monitoringWhen measuring the fill level, pressure sensors use the hydrostatic pressure of the medium in a container to determine the fill level. The basic mechanism works as follows:

- Measurement of hydrostatic pressure: The pressure sensor is positioned at the bottom of the container, where it measures the hydrostatic pressure of the medium. The hydrostatic pressure is directly proportional to the height of the medium above the sensor.

- Conversion to fill level: The measured pressure is converted into a fill level. The sensor can do this through internal calibration and by taking into account the density of the medium.

- Signal transmission: The calculated fill level is then transmitted as an electrical signal to an evaluation system or control unit, where it is displayed or used for further process control.

Honeywell pressure sensors contain an additional gel coating to protect the electronics, enabling use with non-corrosive liquids (e.g., water and saline solution) and in applications where condensation may occur.

For use with aggressive media, it is possible to measure them indirectly via an air column rather than through direct contact with the media.

Thanks to our affiliated production facility, we can assemble, modify, or develop your sensor individually according to your requirements. Our long-standing employees enable us to offer the necessary quality standards in the manufacture of highly sensitive components. Through the continuous expansion and modernization of our machinery, as well as through training our employees, our production is always up to date.

- Temperature: The temperature of the measurement medium and the environment can influence the pressure and thus affect the accuracy of the measurement. It is important to monitor the temperature and make corrections if necessary.

- Humidity: High humidity can lead to condensation, which can affect the accuracy of the measurement. It is therefore important to ensure that the measuring system is protected from moisture.

- Vibrations: Strong vibrations in the environment can affect the accuracy of the measurement. It is advisable to install the measuring system in a stable location and minimize vibrations.

Our solutions

Our product range includes a wide variety of pressure sensors and measuring systems for level measurement. We offer high-quality sensors for various applications and environmental conditions, including demanding industrial environments.

Our plug-and-play solutions

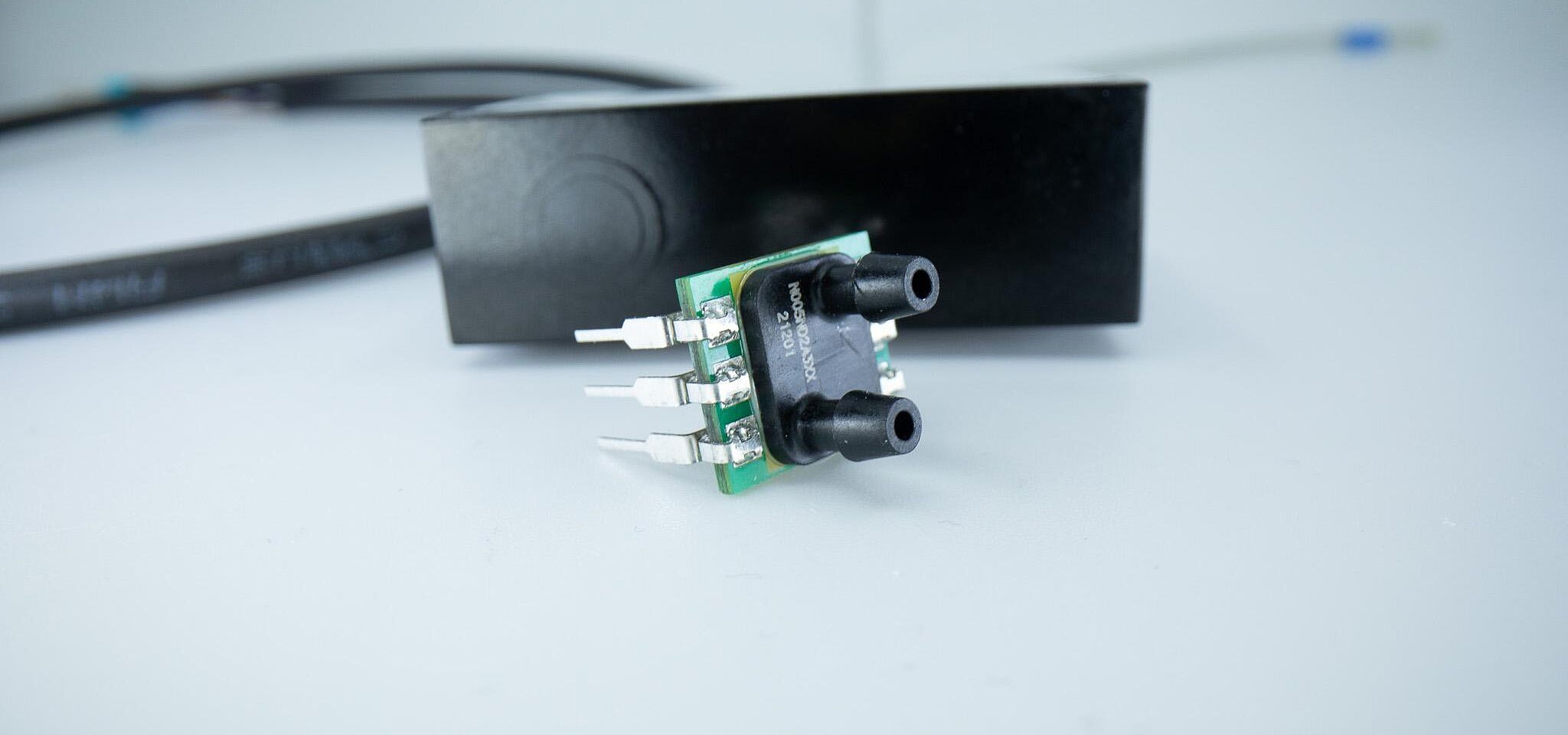

Our compact level monitoring unit for precise measurement applications.

Electronics including pressure sensor and LED voltage indicator encapsulated in plastic housing, providing complete protection against dirt and moisture.

Ports 1 and 2 each with hose connection, cable outlet can be customized to customer specifications.