Level sensors for optical level measurement

Our level sensors offer the option of optical level measurement. This is a precise technology for reliable measurement of liquid levels in a wide variety of applications. In mechanical engineering, our sensors offer a reliable solution for measuring available cooling lubricants or even as leak detectors.

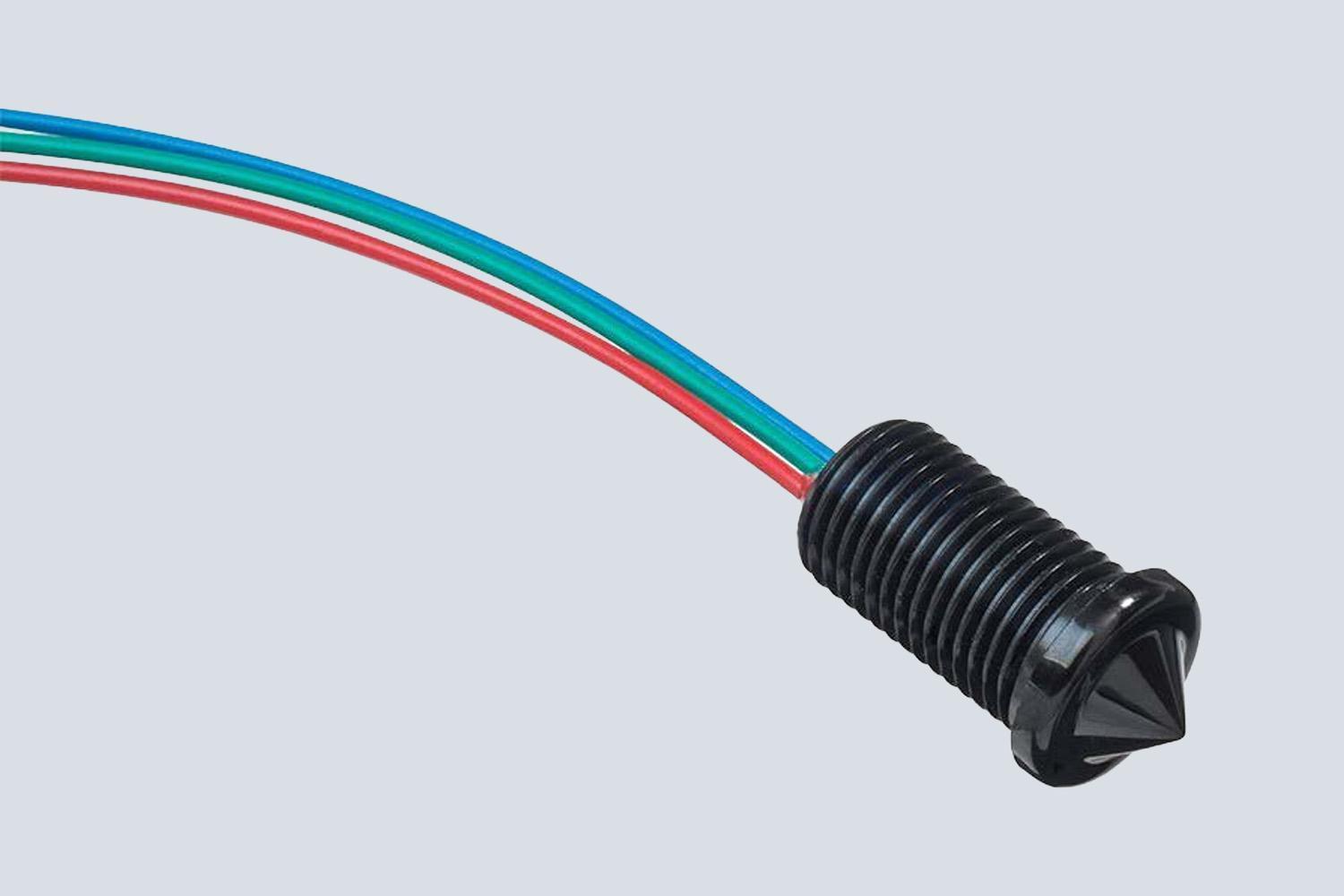

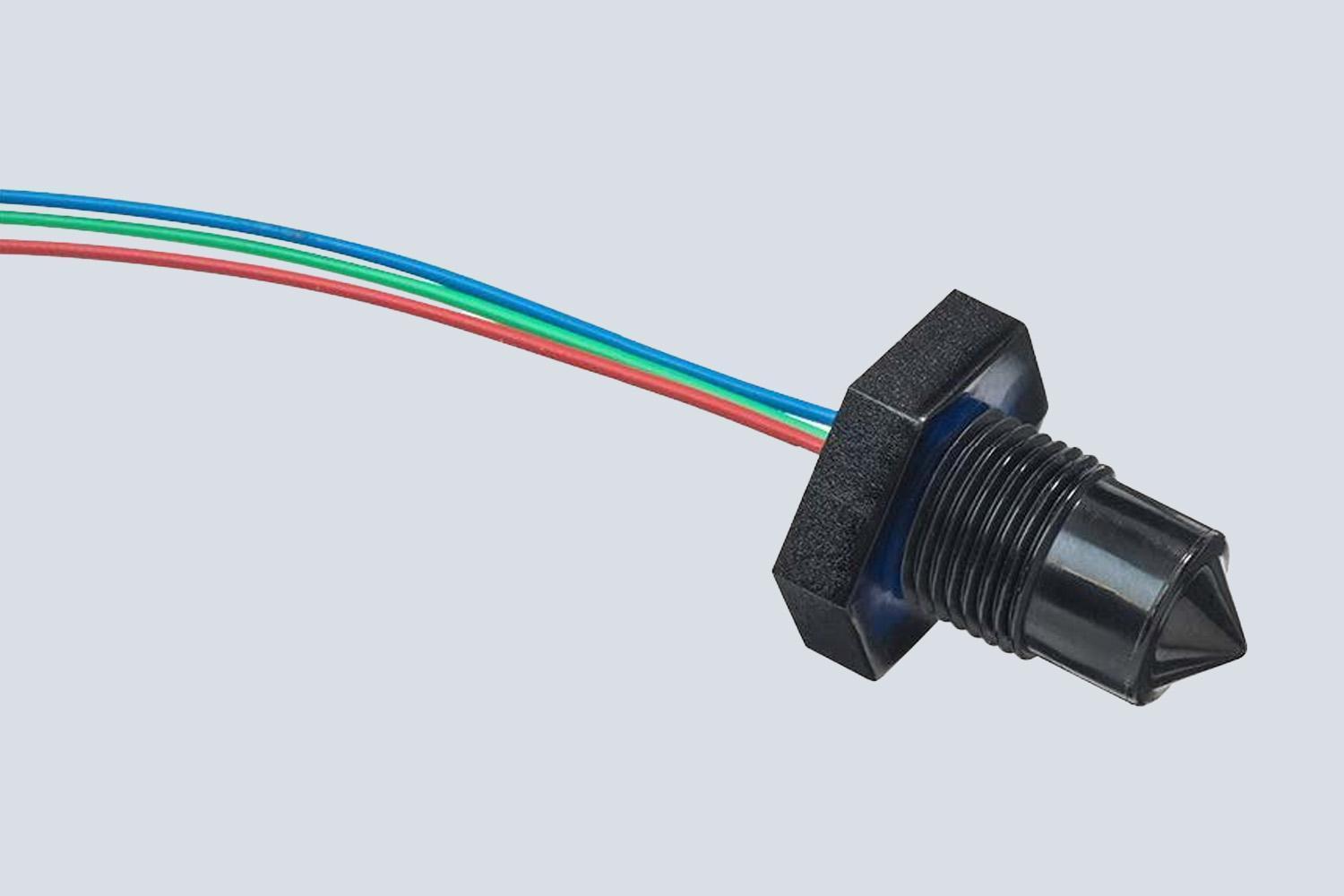

Optomax Liquid Level Switches

Optical level switches use the principle of light refraction and reflection to detect the presence or absence of liquids. Compared to conventional mechanical switches, which are prone to wear and tear and become less reliable over time, this method offers a high degree of accuracy: they perform consistently well even at extreme temperatures, pressures, and in the presence of aggressive chemicals. This versatility makes them ideal for use in a variety of industries, from pharmaceuticals to food and beverage to oil and gas.

The optical level switch uses an infrared LED and a phototransistor, which are positioned precisely at the base of the switch tip. When the tip is in air, the infrared light from the LED inside the tip is reflected back to the phototransistor. When the tip of the switch is immersed in a liquid, the infrared light escapes from the tip and causes a change in the amount of light at the phototransistor, which changes the state of the output.

The sensor can detect the presence or absence of almost any type of liquid, whether oil-based or water-based. This method is insensitive to ambient light and is not affected by foam in the air or small bubbles in the liquid.

Our optical level sensors offer a reliable and precise solution for monitoring liquid levels in a wide range of applications.

- In industry for monitoring:

- Hydraulic fluids

- Water storage tanks

- Submarine torpedo tubes and water separators

- Testing and machine tools

- For automated refilling in:

- Medical technology

- Process control

- Food and beverage industry

Our optical level sensors offer a wide range of advantages and features:

- High precision: Thanks to advanced optical technologies, our sensors achieve extremely precise measurements, even at low or changing fill levels.

- Robustness: The sensors are robust and resistant to extreme temperatures, pressure conditions, and chemical influences.

- Maintenance-free: Optical sensors generally require little maintenance as they contain no mechanical parts that could wear out.

- Fast response times: The sensors deliver immediate results, enabling fast and efficient level monitoring.

- Flexibility: They are suitable for a wide range of liquids and containers, including transparent and opaque liquids.